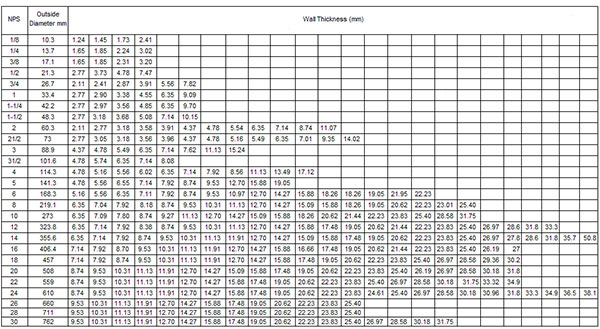

Specification

Seamless Steel Pipe

Process: Seamless Steel Pipe (SMLS STEEL PIPE)

Standard: API 5L, API 5CT, ASTM A106/A53, ASTM A519, JIS G 3441, JIS G3444,

JIS G3445 DIN 2391, EN10305, EN10210, ASME SA106, SA192, SA210, SA213,

SA335, DIN17175, ASTM A179…

Steel Grade:

API 5L :API 5L: GR B, X42, X46, X56, X60, X65, X70

ASTM A53/A106: GR A, GR B, GR CASME SA106: GR.A, GR.B, GR.CASME

SA192:

SA192ASME SA209M: T1, T1a

ASTM A335:P1, P2, P5, P9, P11, P22, P23

ASTM A333:Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9, Gr.10, Gr.11

Mill Test Certificate: EN 10204/3.1B

Wall Thickness

API 5L Line Pipe

STEEL GRADE

API 5L PSL1/PSL2 GR B , X42, X46, X52, X60, X65, X70

STEEL CHEMICAL COMPOSITION

|

STEEL GRADE |

% by mass, Maximum |

||||

|

C |

Si |

Mn |

P |

S |

|

|

GR B |

0.28 |

0.40 |

1.20 |

0.030 |

0.030 |

|

X42 |

0.28 |

0.40 |

1.30 |

0.030 |

0.030 |

|

X46 |

0.28 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X52 |

0.28 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X56 |

0.28 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X60 |

0.28 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X65 |

0.28 |

0.40 |

1.45 |

0.030 |

0.030 |

|

X70 |

0.28 |

0.40 |

1.65 |

0.030 |

0.030 |

MECHANICAL PROPERTIES

|

STEEL GRADE |

Yield strength, min. psi (MPa) |

Tensil strength, min. psi (MPa) |

Elongation in 2 in., min. % |

|

GR B |

245 |

415 |

|

|

X42 |

290 |

415 |

|

|

X46 |

320 |

435 |

|

|

X52 |

360 |

460 |

|

|

X56 |

390 |

490 |

|

|

X60 |

415 |

520 |

|

|

X65 |

450 |

535 |

|

|

X70 |

485 |

570 |

TEST REQUIRED

Chemical Analysis, Mechanical Test, Visusal Inspection , Tension Test, Dimension Check

Bend Test , Flattenting Test, Impact Test, DWT Test, NDT Test

Hydrostatic Test, Hardness Test…..

ASTM A106 Steel Pipe

Grade and Chemical Composition

| Grade |

C≤ |

Mn |

P≤ |

S≤ |

Si≥ |

Cr≤ |

Cu≤ |

Mo≤ |

Ni≤ |

V≤ |

|

A |

0.25 |

0.27-0.93 |

0.035 |

0.035 |

0.10 |

0.40 |

0.40 |

0.15 |

0.40 |

0.08 |

|

B |

0.30 |

0.29-1.06 |

0.035 |

0.035 |

0.10 |

0.40 |

0.40 |

0.15 |

0.40 |

0.08 |

|

C |

0.35 |

0.29-1.06 |

0.035 |

0.035 |

0.10 |

0.40 |

0.40 |

0.15 |

0.40 |

0.08 |

Mechanical Properties:

|

Grade |

Rm Mpa Tensile Strength |

Mpa |

Elongation |

Delivery Condition |

|

A |

≥330 |

≥205 |

20 |

Annealed |

|

B |

≥415 |

≥240 |

20 |

Annealed |

|

C |

≥485 |

≥275 |

20 |

Annealed |